Servo Motion Actuator Replaces Encoder With Position Sensor

Interesting Projects Blog

July 15 2024 | Donald P. Labriola PE

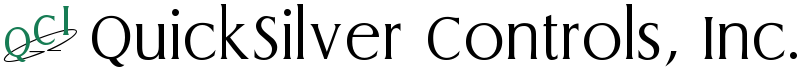

For engineers seeking a motor scaled down in size but not power, QuickSilver

Controls has extended its Mosolver (portmanteau of “motor” and “resolver”)

servo motion actuator into a NEMA 17 frame format. The follow-up to its NEMA

23 Mosolver, the goal was to meet the needs of companies operating spacesensitive

equipment.

The solution adds a position feedback sensor into the structure of a high pole count AC motor,

eliminating the need for an encoder and resolvers. In a tight environment, the use of an encoder

is often difficult, if not impossible, and today’s thin, compact encoders can be cost-prohibitive

and require weeks or months of lead time to source.

The Mosolver actuator combines the motor and resolver into a single package while providing

32,000 counts of position information using a compact nylon sensor coil placed within the stator

opposite the rotor. The result is compact, inexpensive, and robust closed-loop motion control

with good torque.

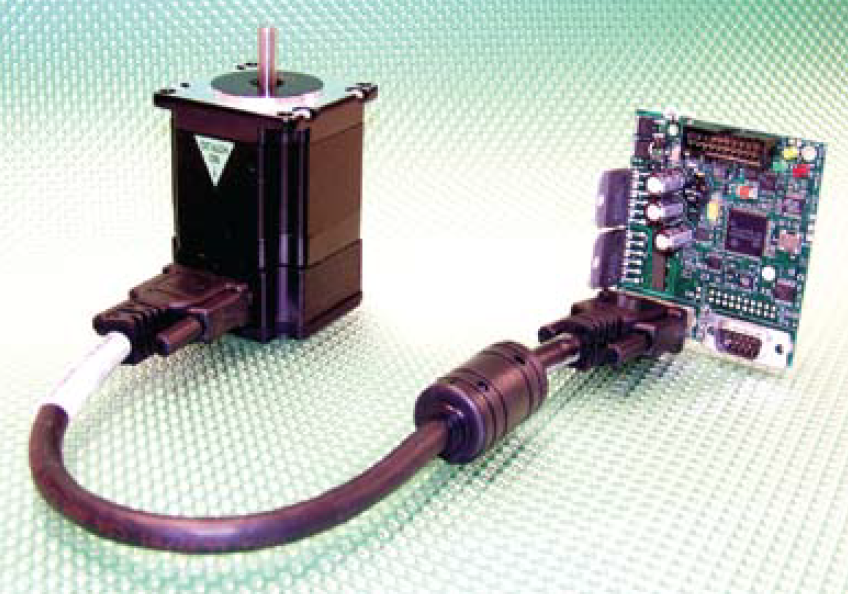

Don Labriola, president of QuickSilver Controls, out of San Dimas, Calif., told Design News that

the primary advantages of removing the encoder is a reduction in size, as well as cost.

“With the encoder size not that much smaller for a (NEMA) 17 frame than a 23 frame, the

overall size reduction, as a percentage, is better as the motor size goes down,” he said. “The

cost of an encoder added to a motor is just part of it. You still need to assemble and align the

resulting system. In a harsh environment, you also need to protect the encoder, which drives up

costs.”

The Mosolver adds a flex circuit to the interior of the motor at assembly time. “The materials are

significantly less than for an encoder, there’s no alignment, and there are no additional housings

needed to protect the device,” Labriola said.

He noted that compared to the motor, the encoder is usually frailer and becomes more so as it’s

scaled down to smaller sizes. It’s also prone to overheating and accumulating grease or dust on

the encoder disk. By getting rid of the most sensitive component and putting the Mosolver into a

smaller package, Quicksilver is looking to expanded market applications. The company has

received custom configuration inquiries.

“We recently received a query for use in a radiation environment,” Labriola told Design News.

“The customer is trying to use encoder disks, and radiation exposure is causing the disks to

darken, which is causing problems. In the Mosolver, everything is passive — there’s no

electronics to be affected by radiation — and the polyamide itself is a highly-rated radiationresistant

material.”

The company believes that a NEMA 17 frame will be particularly attractive to medical and

scientific laboratory environments that are operating small positioning stations. Labs are often

expensive to operate, and most hospitals cannot make nearly as much per square foot of lab as

they do with hospital beds. Equipment for new tests needs to be added regularly, but lab sizes

remain static.

“Size is always a major factor in labs, and keeping it small helps,” Labriola said. “Running

separate motors and keeping them cool takes up a lot more space. If you can keep from making

heat in the first place, you don’t have to add refrigeration.”

Labriola said the company is seeking to expand the technology into larger formats in both frame

size and torque, which could lead to exercise machine applications. Without an encoder,

manufacturers would be free to use a larger motor in a smaller footprint.

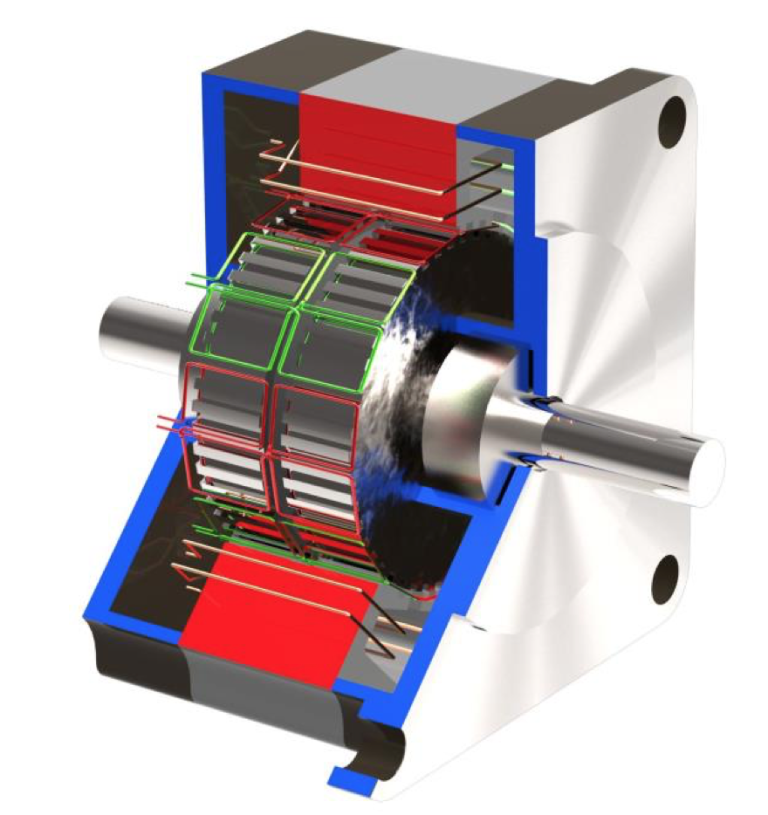

“The alignment is inherent, because it’s using the same magnetic field to run the motor, and

you’re automatically aligned,” Labriola said. “In terms of basic reliability, there are fewer items in

the motor, and you’re already inside a magnetic field.”

QuickSilver is also working on research and development to put its Mosolver technology into a

submersible IP68 package, which would open up a number of pumping and dredging

applications.

This article originally appeared in the August 2015 issue of Design News.

Related Posts

The Hybrid Servo Motor – Stepping up to Closed Loop

The Hybrid Servo Motor – Stepping up to Closed Loop Interesting Projects Blog October 1 2024 | Donald P. Labriola

Motion Control and System Engineering Considerations

Motion Control and System Engineering Considerations Interesting Projects Blog September 22 2024 | Donald P. Labriola PE Motion Control choices